When you leave these courses, you’ll consider the course manual an indispensable on-the-job reference for years to come.Module I: Pre Manufacturing

Introduction

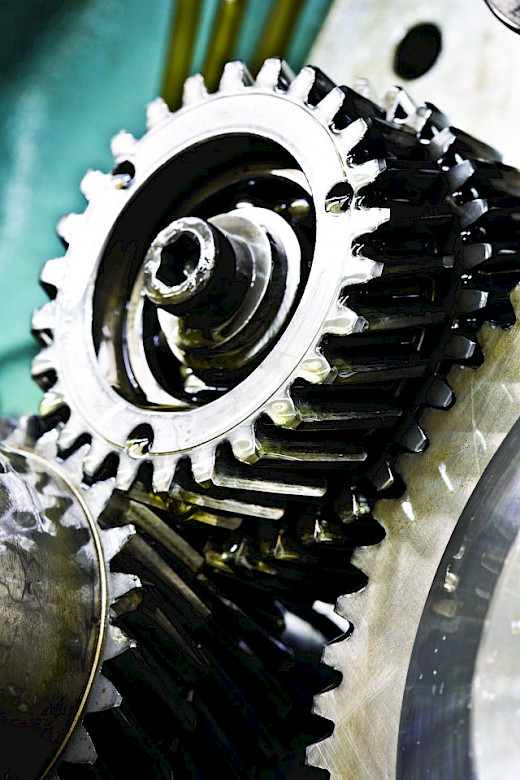

Main Parts

Summary

Module II: Manufacturing

Introduction

Main Parts

Module III: Application of Hydraulics and Troubleshooting

Application of Hydraulics

Hydraulic System

Troubleshooting

Summary

What You Get When You Attend

|

|

info@lubrication-institute.com| (+91) 943 111 7604